``Reliability is very important to us. We want our production equipment to be as low maintenance as possible.``

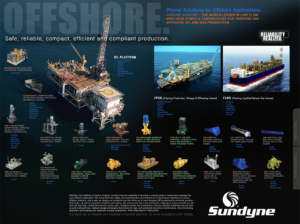

Reliable, Compact and Efficient Pumps and Compressors for Offshore Upstream Oil and Gas Production

Oil and gas production starts at the well head, where offshore operators extract raw crude oil and gas from offshore wells. Once out of the ground, the oil and gas requires an initial round of processing to separate the rich mixture of hydrocarbons, gas, solids and water in preparation for transport to refineries via pipeline, oil tanker, railcar or truck. Sundyne manufactures pumps and compressors that can withstand the rigors associated with offshore drilling and production processes. Sundyne equipment is specifically designed to address the unique application requirements of off-shore platforms and floating platform storage and offloading (FPSO) vessels.

Download Offshore Upstream Oil and Gas Production Literature

Wellhead Production

As well heads extend to deeper depths, the need for pumps that can reliably deliver high-pressures and flows becomes paramount. Capable of running continuously for up to 5 years without the need for service, Sundyne OH6 integrally geared pumps are reliable and able to produce high heads for well injection. They also have a small footprint, which is critical for space savings on a platform or FPSO.

Separation

Offshore wells produce a mixture of gas, condensate and water, along with various other contaminants that must be separated and processed. Sundyne direct drive pumps are ideally suited to execute this process without risk of fugitive emissions or flash vaporization.

Process

Offshore facilities rely critically on the performance of dozens of pumps and compressors operating in varying conditions and rigorous environments. Built to comply with the latest API 685 and 610 (ISO 13709) standards – as well as ASME / ANSI requirements – Sundyne pumps and compressors can stand up to virtually any offshore application.

Offloading and Transfer

Many FPSO facility types require a booster pump as a means for transferring product from the platform to a tanker or pipeline. Sundyne manufactures a wide range of solutions for such applications, including the VS and BB series pumps, and LMC / BMC compressors, which leverage decades of experience designing fluid and gas handling technology for use in the refining, storage and transport sectors.

Produced Water

Water is an essential component of offshore production. Whether it’s desalination or reverse osmosis for providing fresh water to the facility itself, handling seawater for compressor coolers, gas coolers or HVAC applications, or simply providing water at a moment’s notice to fight a platform fire, Sundyne offers a fluid handling solution tailored to any task.

Flare, Vent and Re-injection

Sundyne integrally geared compressors generate high pressures and can safely handle contaminants without risk of exposure to the atmosphere, making them a perfect choice for handling waste-gas for flare, vent or re-injection.

Fuel Gas

After separation, raw gas is moved to the LNG processing plant. There, H2S is removed and sulfur is processed for commercial use. The purified gas is then moved to production in dehydration, where Sundyne compressors are used for amine regeneration and to move the gas to NGL recovery systems where sealless pumps handle the distilled byproducts, including ethane, propane, butane and other gases. Sundyne’s API 685 sealless magnetic drive pumps are also used to move the leftover processed water. The final product is liquefied for transport utilizing Sundyne integrally geared cryogenic compressors.